COOPERATION MODEL

ARTIFICIAL INTELLIGENCE

PRODUCT ENGINEERING

DevOps & Cloud

LOW-CODE/NO-CODE DEVELOPMENT

INDUSTRY

FRONTEND DEVELOPMENT

CLOUD DEVELOPMENT

MOBILE APP DEVELOPMENT

LOW CODE/ NO CODE DEVELOPMENT

EMERGING TECHNOLOGIES

Many logistics companies struggle as their digital systems no longer keep up with the volume and complexity of their operations. The challenges appear in planning delays and long coordination cycles between teams.

Logistic solutions upgrade the core system, improving planning time and solving many core challenges. However, building a custom software system requires a significant amount of investment.

The price of building logistics software varies widely because several layers shape the final number.

When we talk about scope, we're talking about how much of the logistics workflow is included in the first release. A basic transport planning tool might seem simple, but when a team adds warehouse flows, loading guides, driver apps, temperature monitoring, analytics, and customer tracking pages, the project becomes much larger.

The development team needs more time, more testing, and more coordination with internal departments. That's why scope is always the first factor that pushes cost upward.

Many logistics companies use older finance tools or planning databases that still store customer records or shipment data. Connecting new software with older systems takes time because each system stores information in its own structure.

This is one of the most common reasons budgets expand, companies usually underestimate how much data must be cleaned or mapped before it becomes usable.

Many companies now expect route optimization, estimated arrival predictions, temperature alerts, photo-based proof of delivery flows, or dashboards that update every few seconds. These features aren't difficult to build, but they do require experienced software engineers and careful testing because they operate in real time. Each advanced feature increases cost by a clear percentage that we'll cover later.

These three factors together explain why one logistics project might cost around $10,000 while another goes beyond $300,000. The gap comes from the depth of the workflow, not from inflated pricing.

Scope decisions have the strongest influence on budget because they decide what the first version of the software must do. If a company begins with a simple planning system, development can move quickly.

When additional functions such as warehouse coordination or driver applications are planned, the work expands. Each additional function needs its own screens, testing, and workflow adjustments. This is why many companies start with a smaller release before adding larger pieces.

A clear example is the quoting feature that many transport teams use. On its own, a quoting tool with rate rules and customer history can cost around $10,000 to build.

But when the same tool needs integration with real-time tracking or customer portals, the cost moves upward. Companies often underestimate this jump because they see these tasks as simple additions. In reality, each feature adds its own cycle of design, development, testing, and refinement.

These decisions are natural. But when they're not paced correctly, the project timeline grows longer. That's why planning scope with a gradual approach reduces overspending and avoids pressure on operational teams during rollout.

Once the main features are defined, the next major cost comes from integration. This is the work required to connect the new system with your existing data and other tools. Most logistics companies still run a combination of older planning tools, spreadsheets, and basic tracking products. If customer or shipment information lives in several places, the new system must pull that information into one structure.

Every connection to an external system takes 10% to 30% of the cost of that module. If your finance system needs to exchange shipment status, that becomes one integration point. If your customer portal needs to receive tracking updates, that becomes another.

This is why integration isn't an optional part of the budget. It's a core part of the work and should be planned early. When companies skip this planning stage, they face cost increases later in the project.

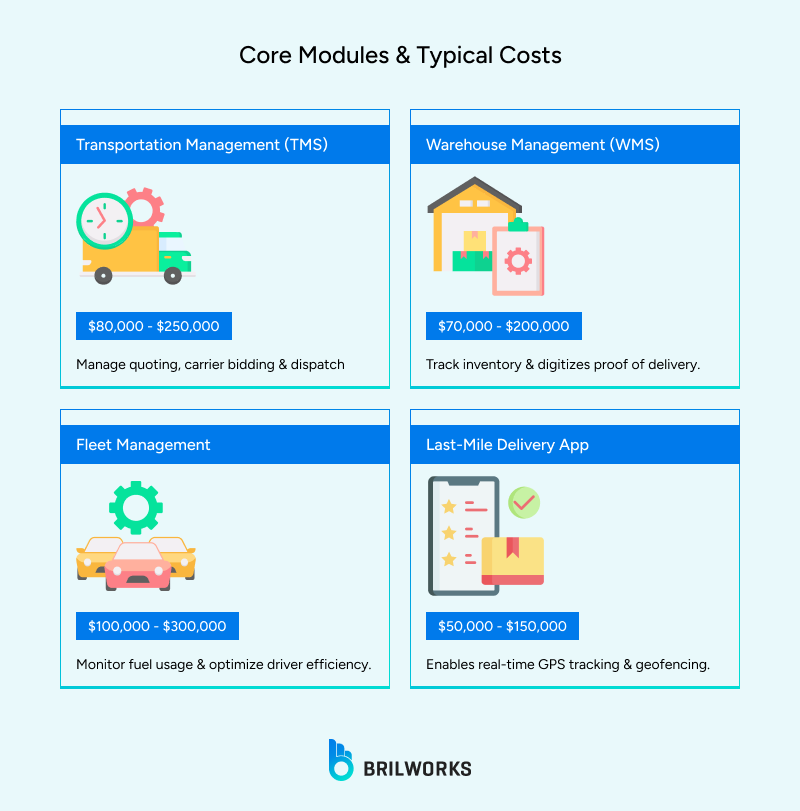

Once scope and integration needs are clear, the next layer of cost comes from the specific modules you choose. Each module has a common cost range because the work involved is predictable across most industries. These ranges are based on data from recent builds across transport companies, warehouse operators, automotive supply chains, and last-mile delivery teams.

Cost range: $80,000 - $250,000

This module helps teams schedule loads, plan routes, and update shipments. The range changes based on how advanced the route planning must be and how many roles use the system. Companies that use such modules often report improvements like 25% fewer pricing mistakes or 40% faster planning cycles.

Cost range: $70,000 - $200,000

Handles picking, stock audits, and proof of delivery entries. When teams shift from manual records to digital records, delivery confirmation times can improve by more than 50% because information flows back instantly.

Cost range: $100,000 - $300,000

This includes fuel monitoring, service scheduling, and driver performance reporting. Many companies report fuel savings of 10% to 15% once they use these tools consistently.

Cost range: $120,000 - $400,000

For larger suppliers or manufacturers, these systems help manage gate entries, trailer movement, and loading areas. When companies use them well, manual entry errors drop almost completely.

Cost range: $50,000 - $150,000

Includes driver apps and delivery confirmation flows. These are common in e-commerce and grocery delivery networks.

Cost range: $8,000 - $20,000

Custom indicators and reporting. These are often added after the main system goes live.

Even though the modules give a high-level picture, companies still need to understand feature-level cost to make accurate decisions. Here are common features and their costs:

Map-based vehicle tracking: $10,000 - $25,000

Route optimization engine: $15,000 - $30,000

Quote generation tool: $8,000 - $15,000

Security and audit trails: $10,000 - $20,000

RFID warehouse visibility: $15,000 - $40,000

Annual maintenance: 15% - 20% of original cost

These numbers matter because they help companies decide what belongs in the first release and what can wait until after launch.

The cost of logistics software shifts depending on the industry because each one has specific requirements.

Cost range: $120,000 - $400,000

Relies heavily on accurate vehicle identification and strict supplier coordination. This increases cost because the software must handle large datasets and precise tracking.

Cost range: $90,000 - $220,000

Need returns management, photo confirmation, and scalable order handling. These features require flexible design because order volumes can change daily.

Cost range: $120,000 - $300,000

Requires temperature monitoring, strict reporting, and reliable tracking. These requirements raise cost because they demand sensors, alerts, and secure data storage.

Cost range: $100,000 - $250,000

Vehicle haul-away or long-haul freight needs accurate rate planning and load scheduling.

Cost range: $60,000 - $180,000

Needs offline capabilities because drivers often work in areas with poor network coverage.

These ranges help companies evaluate where they fall and what specialized features they cannot avoid.

Companies often focus on the build cost and forget the supporting layers that shape the total investment.

A smaller development team of a project manager, two developers, and one quality engineer can deliver a basic system in three to four months. This usually costs $15,000 to $25,000 per month. Larger teams with architects and dedicated operations support can reach $50,000 to $100,000 per month depending on complexity.

Microservice-based platforms or blockchain-backed records increase cost because they require specialist engineers. These choices should be made only when the business case demands them.

Warehouse screens, planning screens, mobile apps, and supervisor panels must all work smoothly together. Quality design reduces training time and prevents mistakes on the floor, but it does add to project timelines.

Most companies have years of shipment records in spreadsheets or older tools. Cleaning this data and preparing it for migration can consume 10% to 25% of the project effort.

Once the system is live, you also need a budget for hosting. A simple system might cost $5,000 to $10,000 a year. A system with heavy automation or AI models might cost $20,000 to $50,000 a year.

These numbers matter because they show that the real investment involves both the build and the long-term maintenance.

There are proven approaches that help companies manage cost while reaching quality outcomes.

Launch a smaller version of the product with only the essential features. This gives teams real usage data that guides later upgrades.

Reuse trusted authentication services, analytics tools, and mapping libraries. Many companies also use open-source route planning tools to avoid building complex logic from scratch.

Working with teams based in India or Eastern Europe can reduce development cost by up to 60% because hourly rates are lower. However, you'll need clear documentation and communication routines. A buffer of around 20% helps account for coordination cycles across time zones.

Avoid early integration with large finance or planning systems unless absolutely necessary. These integrations work best once the core workflow is stable.

Custom logistics software is a significant investment. It demands clear planning, careful scope decisions, and honest assessment of your internal processes. When built well, it strengthens every part of the operation from planning to delivery. When rushed or overloaded with features, it causes delays and unnecessary spending.

Companies that succeed start small, learn quickly, and expand based on real usage. This approach protects budgets and leads to systems that actually support daily work. In a market where a single delayed truck can cost hundreds of dollars per day, better digital systems are no longer optional, they're becoming the foundation of reliable logistics operations in 2025.

Get In Touch

Contact us for your software development requirements

Get In Touch

Contact us for your software development requirements